Anti-corrosive protection

Core activities:

- A jet-blast pretreatment of the surface

- A coat of paint

- Surface layering of gravel and lamination

- Surface layering of jet-blast

- Rubber lining

- Fluorpolymers

- Metallization

- Maintenance of concrete and reinforced concrete constructions

Anti-corrosive protection of cooling systems piping

Applying protective anticorrosive coats both in new and corroded cooling piping in power plant operations for many years already, we have been providing:

- pipe service life extension by approx. 25 years

- corrosion losses stopping

- removal or impurities, corrosion products

- screen scaling removal

- pipe friction reduction

- maintenance-free operation

Applying a digging-free method, following double blasting, dust removal, and 100% moisture removal, we apply a specially modified epoxy highly dry material at the thickness of approx. 1 mm (in several mutually related layers).

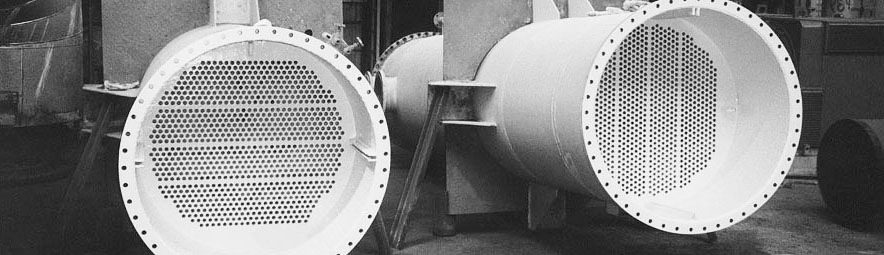

Repairs of condenser piping

Application of the protection system assures:

- the extension of piping durability

- prevention of electrical corrosion

- part-filling of corroded sections of piping

- easier cleaning

- non-maintenance operation

Following the sealing of pipes, two surface coats of sand blasting and the removal of excess dust are applied. After sealing of pipes with rubber seals, two surface coats of jet-sprays and the removal of excess dust are applied. After the removal of rubber seals, a prime jet-spray and the sealing of pipes using polyethylene seals. The prepared pipe is filled with gravel in sequential parts in the required thickness. Following the removal of polyethylene seals and the grinding of the surface and edges, the final jet-spray is applied.

Sand blasting and painting of steel constructions

The sand blasting assures of:

- the removal of impurities such as rust, scales, grease, deposits

- the removal of old paint coats

- the enlarging of guy surfaces - increasing of surface coarseness

Following the surface sand blasting and the removal of excess dust, a paint coat, via the method of brush, rolling or spraying, is applied.

Anti-corrosive systéme for high loading

Anti-corrosive systéme for high loading are gravel application and lamination.

Application of the protection system assures of:

- high tolerance against chemical load

- extraordinary tolerance against mechanical load

- heating tolerance

- high durability

- simple repairable qualities and maintenance

After the surface sand blasting and the removal of excess dust, the prime coat is applied. The primed surface is applied with gravel in the required thickness. The system is concluded via the final coat. It is possible to protect extreme mechanically challenged parts of the construction using glass lamination. The number of laminated layers are determined by loading. The individual layers are vented via rolling and the system is concluded via the final coat.

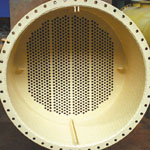

Rubber lining

Applying the rubber lining method, we apply very precise coating in the aggressive environment (surface protection against acids, lye, water vapors...) up to the temperature of 100 °C.

This method is precise because we apply/ glue a prepared produced rubber foil of the thickness of 2, 4, 6 mm on the surface, by which we eliminate potential deviations in the coat thickness, and, therefore, coating is logically of the improved quality and durability.

Apply the primer after both surface abrasive blasting and dirt removal; stick the rubber foil with that using appropriate adhesives (various composition, thickness and vulcanization phase - commensurate with chemical load). This foil is thereafter vulcanized suitably by means of stem, hot air, hot iron, or in pressure cooker to create a compact, highly adhesive layer jointly with the undercoat being ready for loading.

Fluorpolymers

We propose/ apply this coating (PFA, MFA) at most aggressive operation plants (concentrated acids, steams, etc., till the temperature of 260 °C).

We apply also combined resin coats including temporary material to material solutions on various surfaces. Following blasting and application of resin coating or directly on not treated surface, we fix bolts, and, using special attachment (washers, nut, cap) fix on the surface and weld applying continuous seal welding.

Metallization

Metallization is another surface protection method applied by us. We apply hot spraying metals such as Zn, Al, ZnAl, and other metals, on the blasted surface of the grade SA2,3 - 3, Rz 70 μm.

This surface protection is final or it is a part of the anticorrosive system.